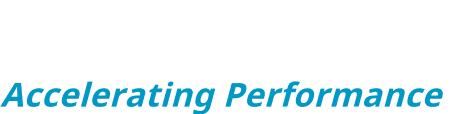

Capacity Optimization Analysis

We model and analyze your current production operation by taking a System Wide approach. This will help you get to your true capacity and give you full Visibility, Insight and Control™.

Our program will be specially customized to your needs. We review your goals and critical drivers, look at your organization, identify your pain points and illuminate new financial opportunities.

Our methodology has its roots in LEAN, Six Sigma, and Theory of Constraints but is augmented with internally developed methods specifically designed for High Mix production environments. We will optimize your resources to deliver maximum capacity. Our analysis will also take into account future growth planning.

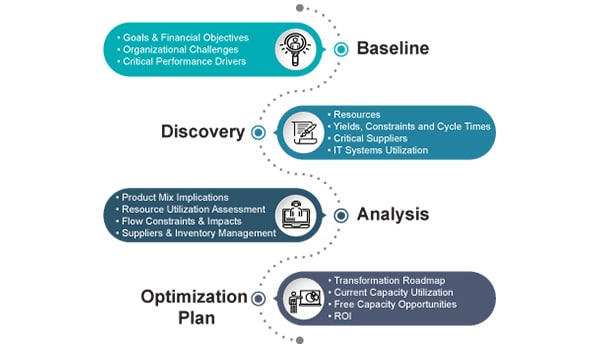

FACTORY/PRODUCTION LAYOUT DESIGN

Our Factory Layout offering should not only be used for your new facility but for your current facility as well. We have seen too many times where a factory does not get redesigned when a new tool, process or product is introduced into an environment. This well-intended change will negatively impact your flow, production and overall efficiency.

This service is an extension of our Capacity Optimization Analysis program. The intent is to ensure that all optimization opportunities are incorporated into a new factory layout, in support of flow within the factory.

CYCLE TIME REDUCTION

Why

There are a number of reasons why you would want to reduce your cycle time. You could do it because you need to meet the demanded order to delivery time by one of your top customers. Reduce your cycle time could also be a way to out perform your competition

How

Focusing on your cycle time forces you to focus on perfecting the in-process quality.

Giving your customers insight into the status of their products through this newly developed process will increase your customer’s satisfaction as well as their trust in your organization to deliver.

Best in class companies can customize products based on customer real-time orders and still deliver faster than their competition.

What

Being able to produce faster will have a positive impact on your WIP and inventory, while still having the resources needed to meet your customers demand and improve your in-process and end-item quality.

Focusing on rapid delivery with the same resources also results in lower product cost, which provides you with a higher profit margin.

ON-TIME DELIVERY IMPROVEMENT

Maintaining On-Time Deliveries (OTD) is essential for a company to satisfy its Customer's needs.

When being compared to competitors, this becomes a key measurement for the Customer when evaluating competitive bids for an order along with cost and quality.

A poor on-time delivery measurement is a strong indicator that somewhere within the value stream and/or your supply chain constraints or yields may be found that must be addressed.

You need to ask yourself, do I have:

- Dissatisfied Customers

- Overstressed employees

- Excessive Overtime

- Higher Operational Costs

- Loss of Future Business due to non-competitiveness

If you find yourself answering yes, then contact CREAN and allow us to conduct a rapid Operational Assessment to identify the issues preventing on-time delivery and the appropriate countermeasures to assist your company in becoming leaders in your marketplace.

PRODUCT QUALITY IMPROVEMENT

Customers do not hope to receive a high quality product but instead expect it. This is another key element that is used by Customers when evaluating a supplier. Therefore, to gain a higher percentage of order wins maintaining a high level of product quality is absolutely imperative.

To many people, Quality Improvement appears to be an impossible task but in reality, in order to achieve a high level of quality takes a systematic approach to identify yield points, their cumulative effect and the appropriate countermeasures.

Poor Quality leads to:

- Dissatisfied Customer

- Excessive Rework

- Higher Operational Costs

- Greater Capacity Requirements

- Late Deliveries

- Poor Employee Morale

- Overstressed Workforce

- Loss of Business

- Loss of Market share

Is your company exhibiting any of the above issues?

Then contact CREAN to perform a rapid Operational Assessment to identify quality issues, their cumulative effect to your operations and the appropriate countermeasures.

OPERATIONAL COST REDUCTION

Maintaining the lowest product cost provides you with a competitive advantage and coupled with systematic cost-control can result in immediate savings.

When speaking of cost reduction most people immediately think of traditional methods to reduce cost (i.e. Reduce Operating Hours, Reduce the Workforce, Reduce Expenses, etc….) All to increase profit margins.

Although cutting costs is the easiest way to improve profitability, it tends to be unsustainable. This forces companies into a vicious cycle of never-ending cost reduction efforts. In addition, these traditional methods tend to overload the workforce and result in poor quality.

So, how do we sustain cost reduction?

We must attack our operational processes not through discrete events but instead by using an enterprise-wide approach to not only understand the impact of individual issues but to clearly see the total impact to the enterprise and how they affect each other.

At CREAN we have developed a proprietary method that provides a rapid Operational Assessment that identifies all issues allowing for a strategic implementation of countermeasures that are coordinated to provide a maximum effect to the company’s profit margin.

Start Your Path to Acceleration Today

Reach out to us and we'll work with you to find the right solution for your engineering or manufacturing needs.