MAPI Support Scenarios

Effective data collection and analysis is critical to optimization. Your Total Factory Assessment covers constraints, yield points, buffer management and batch management, as well as an Outside Processes Assessment. This full picture of your facility allows us to understand its full potential.

MAPI Support Scenarios

Capacity Analysis

Effective data collection and analysis is critical to optimization. Your Total Factory Assessment covers constraints, yield points, buffer management and batch management, as well as an Outside Processes Assessment. This full picture of your facility allows us to understand its full potential.

Quality & Yield Identification

Contextualized data is the key to elevating your performance. We’ll work together to discover the cumulative yield of your production process. We will identify any issues with production, delivery, and cost and mitigation strategies to improve performance.

Creating Flow to Accelerate Deliveries

With consistent data and foundational impact mitigation strategies under way, you start to convert WIP into cash. As you create financial flexibility through predictable on-time deliveries, scheduling, production loading, and work sequencing, you can now fund more advanced optimization projects.

Accelerating Your Path to Excellence

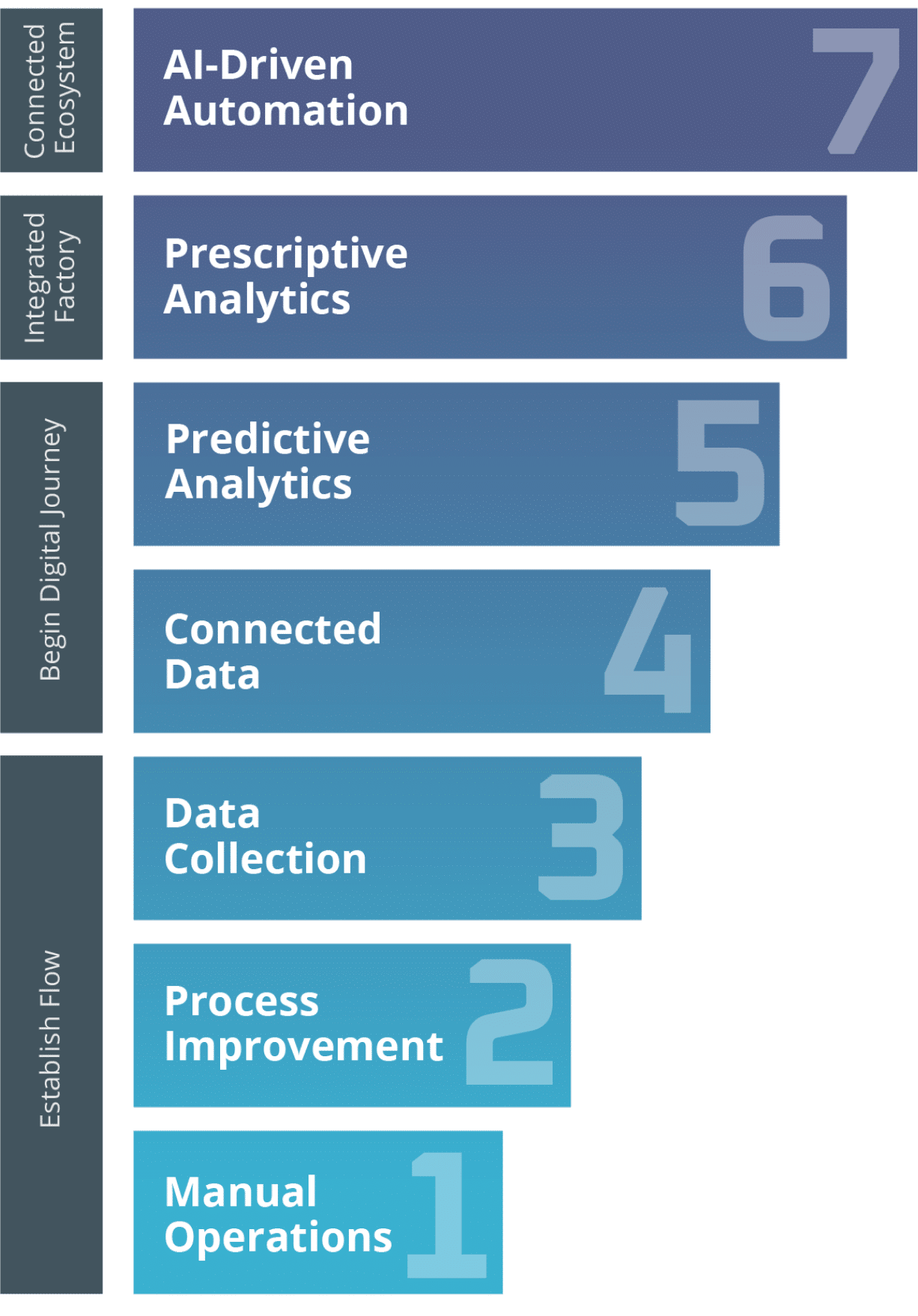

Our 7 Levels of Operational Excellence Assessment is our framework to accelerate evolution from current state to target state. Your progression with KPIs such as Cost, Quality, Schedule, Visibility, Analytics, and Process Control, will be tracked as you work towards your transformation goals.

Find the right expertise to fit your program needs.

Manufacturing Facility Services

- Manufacturing engineering

- Industrial process optimization

- Supply chain management improvement

- Production tools & methods selection

- Electronics & mechanical assembly, integration & test

- Advanced materials and processes

- Composite structures

- 3D printing / additive manufacturing

- Robotics, end effectors & automation

- Design for manufacturability & test

- ERP, MES, production ops analytics

- Smart factory operating systemTM

Are you ready to improve your manufacturing performance?

If you are experiencing symptoms of inefficacy caused by lack of digital integration, well-trained people, and flexible processes, you can get actionable data on where to start your improvement activities.

Establish Flow & VISIBILITY

Focus on people and processes to eliminate inefficiencies to establish flow and streamline data collection to gain visibility to prepare for digital transformation.

Optimize Systems to Gain INSIGHTS

Connect data, analytics, and optimization strategies for predictive analytics as you build more flexible, scalable, high-performing systems.

Achieve Integrated ACCELERATION

Integrate the your facility’s digital and physical flows with supplier data and logistics to achieve prescriptive insights to fortify your production pipeline

WORDS FROM OUR CLIENTS

“ Several difficult issues arose and CREAN quickly brought in additional personnel on an ad-hoc basis with the expertise to define a solution and the technical gravitas to convince the customer it was the right approach. ”

Leading Aerospace Company

Resources

Find the Space Expertise to Fit Your Program Needs

Interim Experts

Have a specific expertise gap that you need to fill fast? Or maybe just a seasoned professional for QA/QC and testing?

Project Consulting

Have an idea and need the team to see it through? CREAN® has dedicated teams across multiple space and manufacturing disciplines at the ready to help you bring your ideas to fruition.