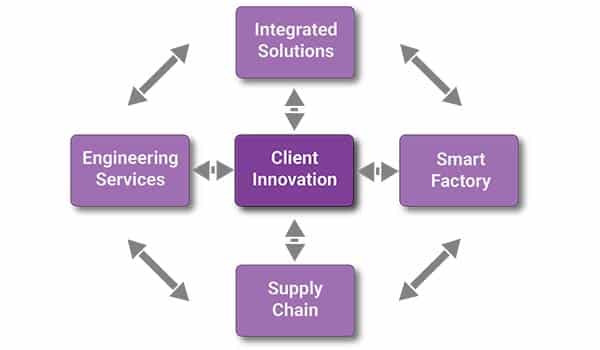

Our Integrated Solutions couples our exceptional engineers, smart factory specialists, and supply chain experts to deliver clients solutions that focus on accelerating their business. Integrated Solutions recognizes that solutions often require breaking down silos with cross-functional solutions that look across the entire business operation to ensure that information, materials, and products flow seamlessly from concept to customer.

PROTOTYPE TO PRODUCTION SOLUTIONS

Using our engineering expertise coupled with our smart factory specialists, we help clients Innovate new products that are both cutting edge in their market but designed for smart manufacturability in a purpose designed and built smart factory. By including engineering and smart manufacturing early, you can significantly improve design solutions, reduce time to market, create highly efficient production solutions, and ensure loyal customers. You own the IP, we just help develop it with your team. We help you innovate and create.

Our Prototype to Production Solutions help clients develop high-end audio solutions here on earth as well as global satellite networks. It is a diverse capability that keeps our engineers engaged on bringing simplified approaches to solving complex, often highly integrated solutions. It doesn’t always take a rocket scientist, but it sure doesn’t hurt to have a couple working side-by-side your team to bounce ideas and skip iterations to get to solutions faster.

SUPPLIER DEVELOPMENT AND SUPPLY CHAIN RE-ALIGNMENT

There are many lessons as a result of the 2020 COVID-19 crisis, but one that is very clear is the criticality of your supply chain. Whether you are a country or a company, you are only as good as your worst critical supplier.

That is why CREAN Integrates our Engineering Services and Smart Factory Transformations services to deliver best in class support to you to make your supply chain robust and integrated into your customer solutions.

Some of the key steps toward a robust supply chain include:

Supply Chain Risk Assessment

This includes assessing past performance and future risks across a matrix of critical factors that identify those risks which if not mitigated could have substantive impact on your ability to dominate in your market. Our supply chain experts coupled with engineering and manufacturing expertise use a proven risk assessment methodology and framework that we customize to your business.

Critical Supplier Review & Development

Our third-party review of your critical suppliers brings value to both you and your most important suppliers. After working with your team to identify the key measures of success to customize our review framework, we work with your suppliers to ensure tight collaboration and ensure that their capacity, capabilities, and communication is aligned with your mutual goals. Our results from our Critical Supplier Development typically leads to significantly improved supplier quality, delivery, and cost. Both parties save significant money, which both strengthens the position of both companies and improves collaboration. After all, don’t you prefer to work with those customers that make you the most money?

Supply Chain Alignment

Let us help you identify the right suppliers for your business. Often overseas suppliers are not the best answer or perhaps should be only part of your solution. Sole sources of critical supplies may need to be realigned to include multiple sources. Is the entire impact and cost of your supplier choices fully booked into the cost and impact on your business? Would a local supplier collaboration result in faster deliveries, lower inventory costs, improved logistics, rapid customization or configuration to meet customer needs, or even lower production costs? Our experienced outside perspective helps clients align their supply chain strategy with their forward-looking business strategy.

Vertical Integration

Sometimes the right answer is not found outside the company, but rather inside. When the right answer is not to outsource but rather to insource, we can help stand up an hybrid organization from your organization and our engineering and manufacturing teams to develop the in-house capability, validate the engineering, production, information systems, and customer response before you fill out your entire team. Once validated, clients backfill those roles we have stood up and move to a full-rate implementation. It is a low-cost way, to work out complete solutions, something like rent before you buy.

Start Your Path to Acceleration Today

Reach out to us and we'll work with you to find the right solution for your engineering or manufacturing needs.